Keep K163 Going

Scraping Bearings

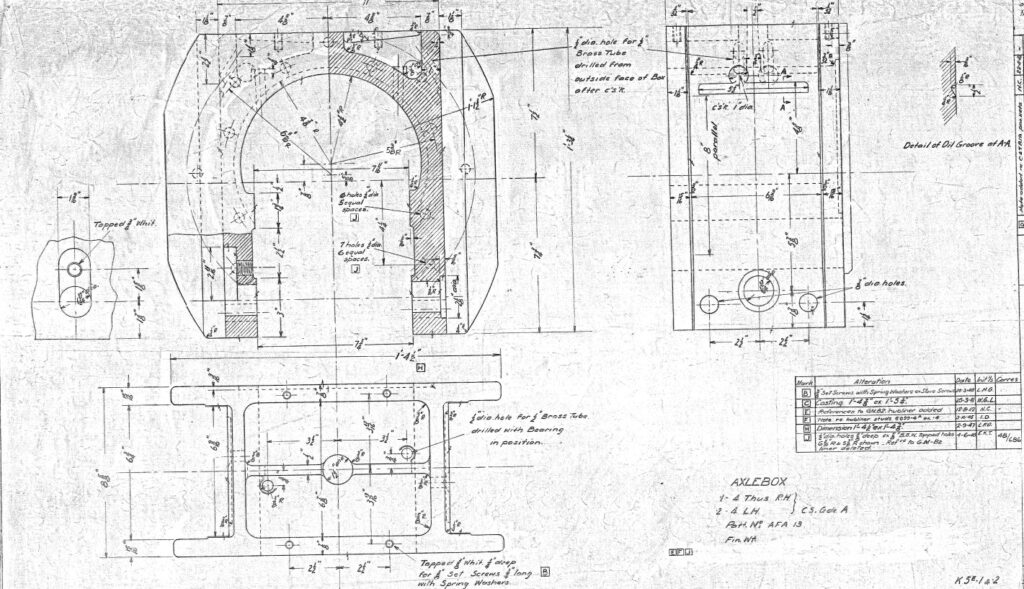

Since the previous update, work on K163 has continued at pace. The skilled task of scraping in whitemetal bearings to achieve proper fitment with the journals is underway.

This task requires applying bearing blue, which is a marking aid, to the journal surface. Then the axlebox is lowered onto the journal so that the bearing seats. The axlebox is then gently rocked back and forth so the marking aid is transferred to the bearing areas in contact with the journal.

Once there is a print on the bearing, the axlebox is lifted off the journal and onto a suitable work bench. A special hand scraping tool is used to remove any high spots so that overall contact is achieved.

With proper contact achieved, this will ensure that the load and weight of the engine is transferred across the journal evenly, minimising the risk of the bearings running excessively hot during the ‘running in’ period.

Once this task is completed, the axleboxes will have the wool pads, trimmings and new felts inserted, oil cellars fitted (to the proper pressure). All this work needs to take place, before the engine can be lifted onto its wheels.